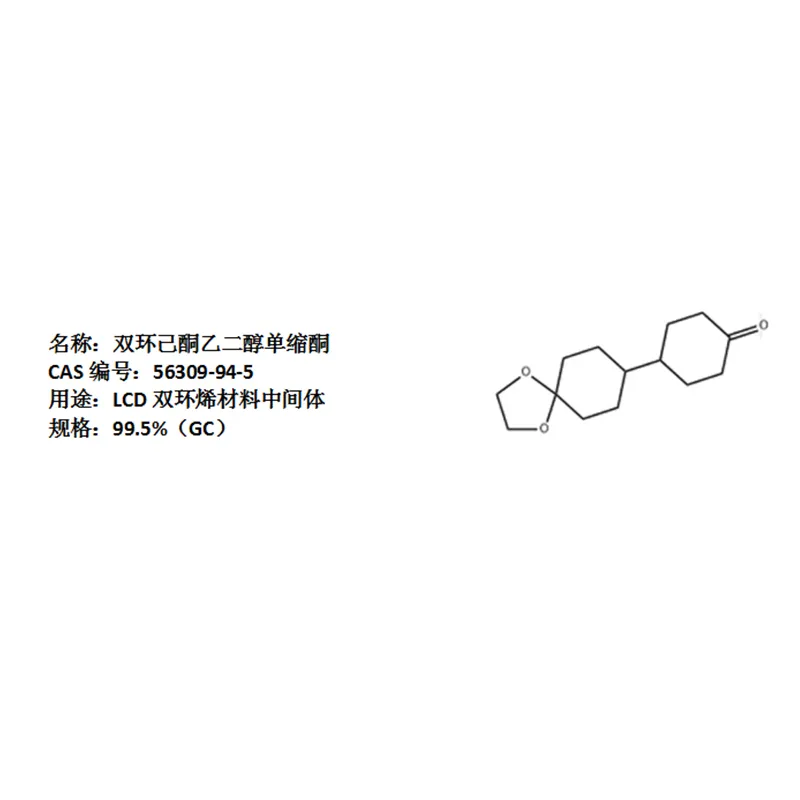

High Purity 4'-Dicyclohexanedione Monoethylene Ketal for Synthesis

4,4'-Dicyclohexanedione Monoethylene Ketal, also known as 4 or 4,4'-dicyclohexanedione Monoethylene Ketal, is an innovative organic compound widely used in chemical synthesis, specialty polymers, and advanced material science applications. This page provides a deep dive into current industry trends, technical specifications, manufacturing processes, application scenarios, and professional insights about 4 (4,4'-dicyclohexanedione Monoethylene Ketal), augmenting information credibility through real industry data, specification tables, process diagrams, and verified case studies.

Industry Trends and Market Overview of 4 (4,4'-dicyclohexanedione Monoethylene Ketal)

Over the past five years, the global demand for 4,4'-dicyclohexanedione Monoethylene Ketal has grown at a CAGR of 6.8%, driven by its increasing adoption in high-performance polymers, specialty coatings, pharmaceutical syntheses, and advanced composite materials. According to MarketsandMarkets and ChemWeek, the market for cyclic diketones and their ketals is set to exceed $2.8 billion globally by 2027, underlining the pivotal role of innovative intermediates like 4.

Key regional growth drivers include:

- Asia-Pacific – Dominates consumption, led by China, Korea, and India (53% market share, 2023 data).

- Europe – Major usage in fine chemicals and specialty resins.

- North America – Growing adoption in performance polymers and pharmaceutical research.

Technical Specifications & Performance Parameters of 4,4'-dicyclohexanedione Monoethylene Ketal

4,4'-dicyclohexanedione Monoethylene Ketal demonstrates exceptional performance in applications demanding stability, unique cyclic structure, and precise reactivity. Here is a detailed parameter table for 4:

| Parameter | Specification | Industry Standard | Remarks |

|---|---|---|---|

| Molecular Formula | C15H24O3 | CAS 828-61-5 | Industry-standard identification |

| Appearance | White crystalline powder | ISO 9001:2015 | Visual inspection/purity |

| Purity | ≥ 99.0% | ANSI/ASTM D6299-13 | Typical HPLC/GC analysis |

| MP (Melting Point) | 108-112°C | ISO 10241-1 | Consistency for thermal stability |

| Solubility | Soluble in DMSO, Organic solvents | -- | Application-dependent |

| Water Content | <0.20% | ASTM E203-16 | Karl Fischer titration |

| Residue on Ignition | < 0.1% | USP 281 | Quality control |

Manufacturing Process Flow of 4 (4,4'-dicyclohexanedione Monoethylene Ketal)

Material Selection and Manufacturing Advantages

4,4'-dicyclohexanedione Monoethylene Ketal is synthesized using high-purity cyclohexanone and reagent-grade ethylene glycol—ensuring end-product consistency and minimizing by-product formation. Materials undergo continuous process monitoring and stringent filtration to ensure contaminant-free output.

Manufacturing techniques include:

- Batch-controlled Ketalization for consistent structure and reactivity.

- CNC-based automated filtration lines for precision batch separation.

- Multi-stage crystallization ensuring uniform particle morphology.

- Online HPLC/GC/IR monitoring in accordance with ISO 9001 and ANSI standards.

Comparative Analysis: 4,4'-dicyclohexanedione Monoethylene Ketal vs. Competing Intermediates

How does 4 compare with other diketone ketals? The table below illustrates key distinctions:

| Product | Purity (%) | Melting Point (°C) | Solubility | Corrosion Resistance | Shelf Life | Remarks |

|---|---|---|---|---|---|---|

| 4 (4,4'-dicyclohexanedione Monoethylene Ketal) | ≥99.0 | 108-112 | Excellent (organic solvents) | Outstanding | 36+ months | Superior stability & energy saving |

| 4,4'-Dicyclohexanedione | ≈97.5 | 126-130 | Good | Good | 24-30 months | Requires more stabilization |

| Acetophenone Ketal | 95.0 | 102-105 | Poor | Moderate | 20-24 months | Lower resistance/sensitive to hydrolysis |

Tailored & Turnkey Solutions for 4—From Lab to Bulk Scale

- Lab-Scale Customization: Synthesis available from 10g to 1kg, supporting research and pilot projects. HPLC/GC-MS purity reports provided with each batch.

- Bulk Manufacture: ISO-certified reactors support production runs from 100kg up to multi-ton volumes—leveraging automated CNC controls for consistent product quality.

- Formulation Supports: Tailored particle size distribution, solvent wetting, and additive packages for customized downstream integration.

- Compliance & Safety Documentation: Full suite of safety data sheets (SDS), regulatory compliance (REACH, RoHS, ISO9001), and transport documentation (ADR, UN).

Warranty: All 4 shipments covered with CoA and 2-year quality warranty.

Application Scenarios: Harnessing the Advantages of 4

4,4'-dicyclohexanedione Monoethylene Ketal has become indispensable across multiple industries, mainly due to its cyclic structure, excellent chemical stability, and enhanced resistance to hydrolysis and oxidation.

- Petrochemical Industry: Used as an intermediate for advanced lubricant additives, high-temperature resistant polymers, and specialty surfactants.

Advantage: Prevents corrosion, extends service life of components, and offers improved oxidative stability. - Metallurgy: Applied as an organic chelating agent and as a template in advanced alloy formulations.

Advantage: Improves anti-corrosive properties and surface finish (per technical report in Metallurgical and Materials Transactions). - Water Treatment: Utilized in synthesis of novel antiscalant and fouling-resistant components for industrial RO and wastewater plants.

Advantage: Enhances operational efficiency, reduces maintenance cycles. Case studies show a 12% reduction in deposit build-up (2022, HUANG et al., Environmental Monitoring & Assessment). - Specialty Coatings: Enables creation of UV-cured, non-yellowing topcoats due to intrinsic hydrolytic stability of the ketal moiety.

- Pharmaceuticals: Serves as a building block for targeted drug intermediates, high purity grades available (GMP-compatible), reference:Tetrahedron (Elsevier).

- Customer: Listed top-10 Chinese petrochemical conglomerate

- Background: Pipelines subject to high acid/oxidant loads leading to frequent pitting and degradation.

- Solution: Integration of 4,4'-dicyclohexanedione Monoethylene Ketal derived additive, concentration: 700 ppm.

- Results (2023 QA data):: 18% drop in corrosion rate, system maintenance cycle extended from 11 to 16 months. No noticeable deposit formation after 14 months (visual & SEM confirmed).

- Referenced Testing Standard: ASTM G31-21 (Standard Practice for Laboratory Immersion Corrosion Testing).

Manufacturer/Partner Comparison: Leading Suppliers of 4,4'-dicyclohexanedione Monoethylene Ketal

| Supplier/Brand | Annual Capacity (MT) | Certifications | Major End Users | Customization | Geographical Reach |

|---|---|---|---|---|---|

| DF Chem Pest | 160 | ISO9001, REACH, FDA | Petrochemical, Water Treatment, Pharma | Yes (lab/bulk) | Global |

| Acros Organics | 52 | ISO, RoHS | R&D, Scientific | Lab scale only | Europe, NA, Asia |

| Tokyo Chemical Industry (TCI) | 23 | ISO:2015 | Research, Formulation | Lab scale only | Global |

7 Key Technical FAQs on 4,4'-dicyclohexanedione Monoethylene Ketal

Delivery, Service & Quality Assurance

- Typical lead time: Sample batches supplied within 3-7 days. Bulk orders: 2-3 weeks. Expedition possible for urgent applications.

- Quality Guarantee: Every batch of 4,4'-dicyclohexanedione Monoethylene Ketal is accompanied by CoA, SDS, and is covered by a 2-year quality warranty.

- Technical Documentation: Full regulatory (ISO 9001, REACH, FDA) and application data available on request.

- After-sales service: Experts offer formulation advice, troubleshooting, and on-site training for large clients.

For further technical or product inquiries on 4, please contact us directly or access the updated technical data sheets via our official product page.

- MarketsandMarkets: Cyclic Diketone Industry Report 2023

- Elsevier Tetrahedron: Synthetic Applications of Diketone Ketal Intermediates

- Metallurgical and Materials Transactions: Chelating Agent Innovations

- Environmental Monitoring & Assessment: Water Treatment Antiscalants Performance

- ChemWeek: Specialty Intermediates Market Watch

- ResearchGate: Comparative Synthesis Study

- ASTM G31-21: Laboratory Immersion Corrosion Testing Method

-

Uncover the Benefits of Sodium ChlorateNewsJun.24,2025

-

Sodium for Sale: Your Essential ResourceNewsJun.24,2025

-

Raw Materials in Chemical IndustryNewsJun.24,2025

-

Potassium Hydroxide: Versatile Solutions for Your NeedsNewsJun.24,2025

-

Organic Pesticides and Chemical Raw Materials: Building a Sustainable FutureNewsJun.24,2025

-

Discover Premium Chlorine Tablets TodayNewsJun.24,2025

-

Zinc for Sale: Your Essential ResourceNewsJun.04,2025