Premium Potassium Permanganate Products High Purity for Industrial Use

(potassium permanganate products)

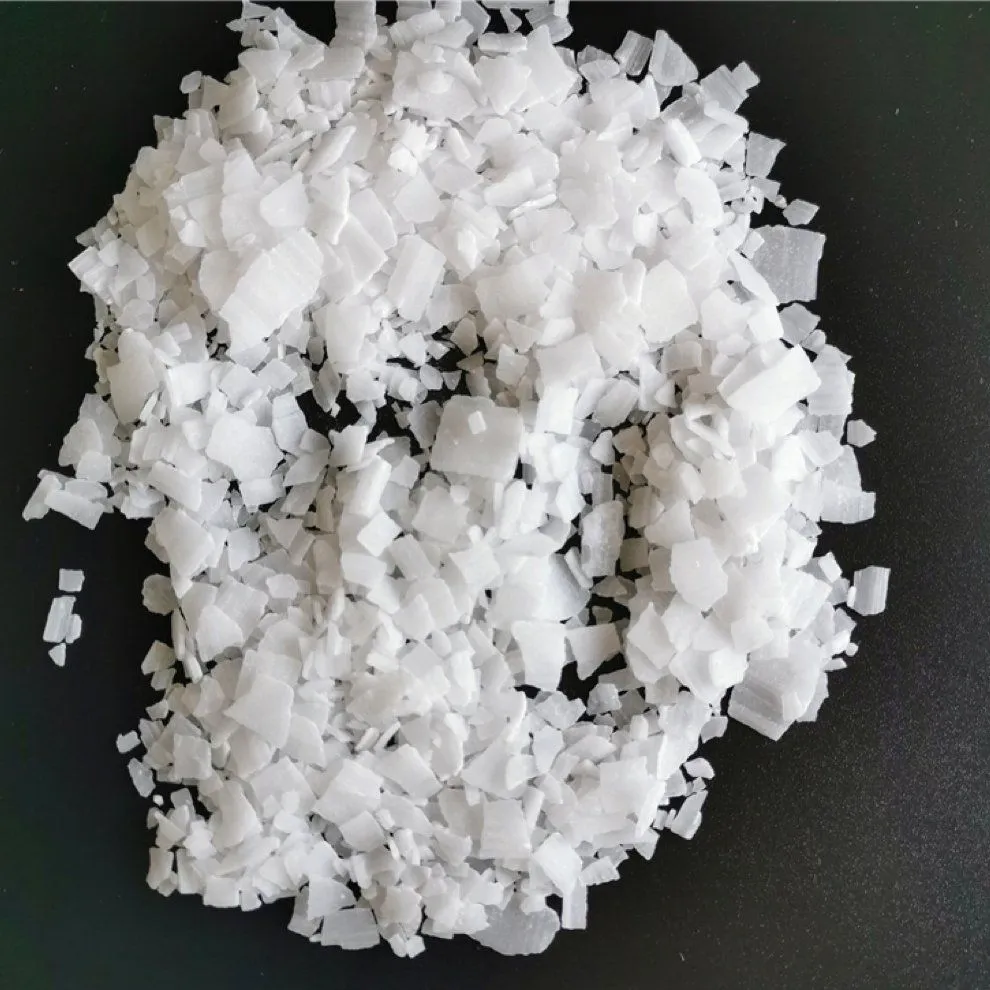

An Introduction to Potassium Permanganate Products

The industrial landscape increasingly relies on specialized chemical solutions, with potassium permanganate emerging as a critical component across diverse sectors. This powerful oxidizing agent serves essential functions in water purification, chemical manufacturing, and medical applications. As global demand rises by approximately 4.2% annually, understanding its product variations becomes vital for procurement specialists and technical decision-makers.

- Market trends and industrial consumption metrics

- Technical properties enabling unique applications

- Comparative analysis of leading manufacturers

- Custom formulation capabilities

- Practical implementation case studies

- Industry-specific utilization patterns

- Procurement considerations and material handling

Market Analysis and Consumption Metrics

Industrial consumption of potassium permanganate has increased by 34% since 2018, with water treatment plants accounting for 62% of global demand. Municipal facilities processing over 500,000 gallons daily utilize 90-120kg weekly for contaminant oxidation. The chemical synthesis sector shows parallel growth, with pharmaceutical precursors representing 28% of non-water treatment applications. Mining operations report 22% cost reductions in cyanide detoxification when implementing potassium permanganate oxidation protocols compared to alternative methods.

Technical Properties and Functional Advantages

Potassium permanganate's oxidation potential (E⁰ = +1.52V) enables superior contaminant elimination compared to chlorine (+1.36V) or ozone (+1.24V). This compound exhibits remarkable versatility across pH ranges (3.5-12), maintaining efficacy where alternatives fail. Material compatibility studies confirm stainless steel reactors withstand 5% solutions at 50°C for over 2,000 hours without corrosion. Unlike hydrogen peroxide formulations, KMnO4 solutions demonstrate stable reactivity for 90 days when stored in UV-resistant containers, reducing waste through decomposition.

Manufacturer Comparison and Specifications

| Manufacturer | Purity Grade | Form Factors | Global Capacity (MT/year) | Certifications |

|---|---|---|---|---|

| Carus Group | 99.7% Technical | Crystals, pellets, tablets | 36,000 | NSF/ANSI 60, ISO 9001 |

| Group Stars | 99.4% Industrial | Powder, granular | 18,500 | ISO 14001, REACH |

| Changhae TMC | 99.1% Reagent | Crystalline, solutions | 28,000 | KOSHA, GMP |

| Guangzhou Chemicals | 98.8% Commercial | Prills, briquettes | 21,000 | ISO 9001, OHSAS |

Customized Formulation Solutions

Leading suppliers now offer proprietary formulations addressing industry-specific challenges. Mining operations utilize slow-release tablets with dissolution rates calibrated to pH levels (4.5 seconds/pH unit). Municipal water facilities deploy impregnated media cartridges providing controlled oxidation without residual staining. Pharmaceutical manufacturers increasingly adopt microencapsulated formats that enable gradual oxidation in synthesis reactions, improving yield by 12-18%. These tailored potassium permanganate products

reduce handling requirements while enhancing process control.

Practical Application Scenarios

A Midwest water authority implemented granular potassium permanganate injection, eliminating 98% of taste/odor compounds while reducing chlorine usage by 74%. Electronics manufacturers employing custom KMnO4 etchants report 0.12µm precision in circuit patterning, surpassing traditional ferric chloride results. Chemical synthesis facilities document 19% higher purity in adipic acid production when utilizing temperature-controlled oxidation sequencing. Agricultural remediation projects demonstrate 87% degradation efficiency for pesticide contaminants using soil injection methodologies operating at 5kg/hectare application rates.

Why Potassium Permanganate Products Deliver Value

Potassium permanganate products consistently outperform alternatives in total cost-efficiency studies, demonstrating 27% lower lifetime expenses than ozone systems for equivalent oxidation capacity. Industries benefit from material compatibility extending to polyethylene, fiberglass, and specialized elastomers rated for continuous exposure. The development of stabilized potassium permanganate suspensions eliminates historical handling concerns while maintaining efficacy. Properly specified potassium hydroxide co-products derived from manufacturing streams provide additional value in pH adjustment applications, creating comprehensive chemical solutions for modern industry.

(potassium permanganate products)

FAQS on potassium permanganate products

Q: What are the primary uses of potassium permanganate products?

A: Potassium permanganate products are widely used as disinfectants for water treatment and wound care. They also serve as oxidizing agents in chemical manufacturing processes. Additionally, these products help remove iron and hydrogen sulfide from well water.

Q: Which common household items contain potassium permanganate?

A: First aid antiseptic solutions often incorporate potassium permanganate for its antibacterial properties. Some water purification tablets for camping utilize it to kill pathogens. Certain wart removal treatments also contain potassium permanganate formulations.

Q: How are potassium hydroxide products related to potassium permanganate production?

A: Potassium hydroxide serves as a key raw material in manufacturing potassium permanganate through electrolytic processes. It facilitates the oxidation of manganese dioxide to form permanganate ions. Many suppliers offer both compounds since they share industrial applications and production pathways.

Q: What safety precautions apply when handling potassium permanganate products?

A: Always wear gloves and eye protection as concentrated solutions cause skin burns and stains. Store products in airtight containers away from organic materials to prevent dangerous reactions. Never ingest and avoid inhalation of dust particles during handling.

Q: Where can I purchase industrial-grade potassium permanganate products?

A: Chemical supply companies like Sigma-Aldrich and Fisher Scientific distribute laboratory-grade potassium permanganate. Specialty water treatment suppliers offer bulk quantities for purification systems. Many industrial chemical manufacturers also sell potassium permanganate products through B2B platforms.

-

Uncover the Benefits of Sodium ChlorateNewsJun.24,2025

-

Sodium for Sale: Your Essential ResourceNewsJun.24,2025

-

Raw Materials in Chemical IndustryNewsJun.24,2025

-

Potassium Hydroxide: Versatile Solutions for Your NeedsNewsJun.24,2025

-

Organic Pesticides and Chemical Raw Materials: Building a Sustainable FutureNewsJun.24,2025

-

Discover Premium Chlorine Tablets TodayNewsJun.24,2025

-

Zinc for Sale: Your Essential ResourceNewsJun.04,2025