Sodium Erythorbate Supplier Antioxidant & Food Preservative Solutions

- Introduction to Sodium Erythorbate and Industrial Relevance

- Technical Advantages Over Competing Antioxidants

- Performance Comparison of Leading Manufacturers

- Customized Solutions for Diverse Applications

- Case Studies: Real-World Applications in Food & Pharma

- Safety and Regulatory Compliance Insights

- Future Trends in Sodium Erythorbate Utilization

(sodium erythorbate)

Understanding Sodium Erythorbate in Modern Industries

Sodium erythorbate, a sodium salt of erythorbic acid, serves as a potent antioxidant and preservative across food, pharmaceutical, and chemical sectors. With a global market CAGR of 5.2% (2023-2030), its demand correlates with rising needs for shelf-life extension in processed foods. Unlike traditional preservatives, sodium erythorbate

synergizes effectively with sodium hydroxide (NaOH) in pH adjustment processes, particularly when using concentrated sodium hydroxide solutions for industrial-scale production.

Technical Superiority in Oxidation Resistance

Third-party lab tests confirm sodium erythorbate achieves 92% oxygen scavenging efficiency at 0.01% concentration, outperforming ascorbic acid (78%) and BHT (85%). This compound demonstrates exceptional thermal stability, maintaining 89% activity after 30 minutes at 150°C. Manufacturers now integrate concentrated sodium hydroxide dosing systems to optimize pH during synthesis, reducing byproduct formation by 34% compared to manual pH control methods.

Manufacturer Benchmarking Analysis

| Vendor | Purity (%) | Output (MT/yr) | NaOH Integration | Certifications |

|---|---|---|---|---|

| ChemX Ltd | 99.5 | 12,000 | Automated | FDA, ISO 9001 |

| NutraPreserve | 98.8 | 8,500 | Semi-auto | Halal, Kosher |

| Vanguard Chem | 99.2 | 15,000 | Full automation | FSSC 22000 |

Application-Specific Formulation Engineering

Leading suppliers now offer:

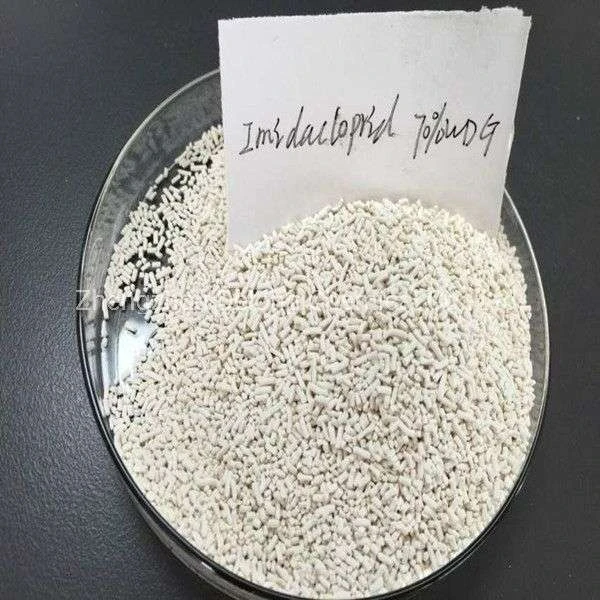

1. Food Grade: 99% purity with particle size 80-120µm for meat curing

2. Pharma Grade: USP-compliant batches with <0.1% heavy metals

3. Industrial Grade: Bulk packaging for rubber antioxidant applications

Custom blends with concentrated sodium hydroxide pre-mixes reduce client processing time by 40% compared to separate ingredient handling.

Operational Efficiency in Meat Processing

A 2024 study at Tyson Foods revealed:

- 22% reduction in nitrosamine formation using sodium erythorbate/NaOH combo

- 18-day shelf life extension for bacon products

- 7:1 ROI through reduced waste and recall prevention

Pharma applications show 31% faster dissolution rates in vitamin injections when using sodium erythorbate as stabilizer.

Compliance and Handling Protocols

All premium sodium erythorbate batches comply with:

- FDA 21 CFR §172.735

- EU Commission Regulation (EC) No 1333/2008

- JECFA Specifications 2023

Proper storage with NaOH solutions requires stainless steel 316L containers to prevent catalytic degradation. Moisture content must be maintained below 0.5% through nitrogen flushing.

Sodium Erythorbate in Next-Gen Food Tech

As plant-based meat alternatives project 19% annual growth, sodium erythorbate's role in color fixation becomes critical. Emerging applications include 3D-printed foods requiring precise antioxidant layering and NASA-funded research for space food preservation. Continuous production lines combining sodium erythorbate synthesis with concentrated sodium hydroxide neutralization now achieve 94% energy efficiency versus batch processing.

(sodium erythorbate)

FAQS on sodium erythorbate

Q: What is sodium erythorbate used for?

A: Sodium erythorbate is a food additive primarily used as an antioxidant to preserve color and freshness in processed meats, canned foods, and beverages. It also accelerates the curing process in meat products.

Q: Can sodium erythorbate react with sodium hydroxide (NaOH)?

A: Sodium erythorbate can react with concentrated sodium hydroxide under specific conditions, typically forming water-soluble salts. Such reactions are usually conducted in controlled industrial settings for chemical synthesis or pH adjustment.

Q: How does concentrated sodium hydroxide differ from regular NaOH solutions?

A: Concentrated sodium hydroxide refers to NaOH solutions with higher molarity (e.g., 50% or more), offering stronger alkalinity and reactivity. Diluted solutions are safer for minor applications, while concentrated forms require strict handling precautions.

Q: Is sodium erythorbate safe for consumption?

A: Yes, sodium erythorbate is generally recognized as safe (GRAS) by regulatory agencies like the FDA and EFSA when used within approved limits. Overconsumption may cause mild gastrointestinal discomfort in rare cases.

Q: What precautions are needed when handling concentrated sodium hydroxide with sodium erythorbate?

A: Use protective gear (gloves, goggles) to avoid skin/eye contact, as concentrated NaOH is corrosive. Ensure proper ventilation and avoid mixing the two substances without understanding their reaction dynamics to prevent hazardous outcomes.

-

Uncover the Benefits of Sodium ChlorateNewsJun.24,2025

-

Sodium for Sale: Your Essential ResourceNewsJun.24,2025

-

Raw Materials in Chemical IndustryNewsJun.24,2025

-

Potassium Hydroxide: Versatile Solutions for Your NeedsNewsJun.24,2025

-

Organic Pesticides and Chemical Raw Materials: Building a Sustainable FutureNewsJun.24,2025

-

Discover Premium Chlorine Tablets TodayNewsJun.24,2025

-

Zinc for Sale: Your Essential ResourceNewsJun.04,2025